We are pioneering the use of integrated, computer-based systems comprised of simulation, analytics and advanced process optimisation tools to develop autonomous reaction systems. These systems are employed to identify kinetic models online for model-based reaction process optimisation and control in the course of unmanned experimental campaigns.

Digital twins

In the Industry 4.0 era, the rapid development of robust pharmaceutical and chemical processes is hampered by the time and effort required to obtain fast, highly predictive and reconfigurable mathematical models to be used in “digital twins”, i.e., digital surrogates of the processes, for agile in-silico testing, design, optimisation and control of chemical processes. An accurate description of the reaction kinetics and heat and mass transfer phenomena occurring in the actual reaction processes is critical and requires extensive experimentation, time, and human and analytical resources.

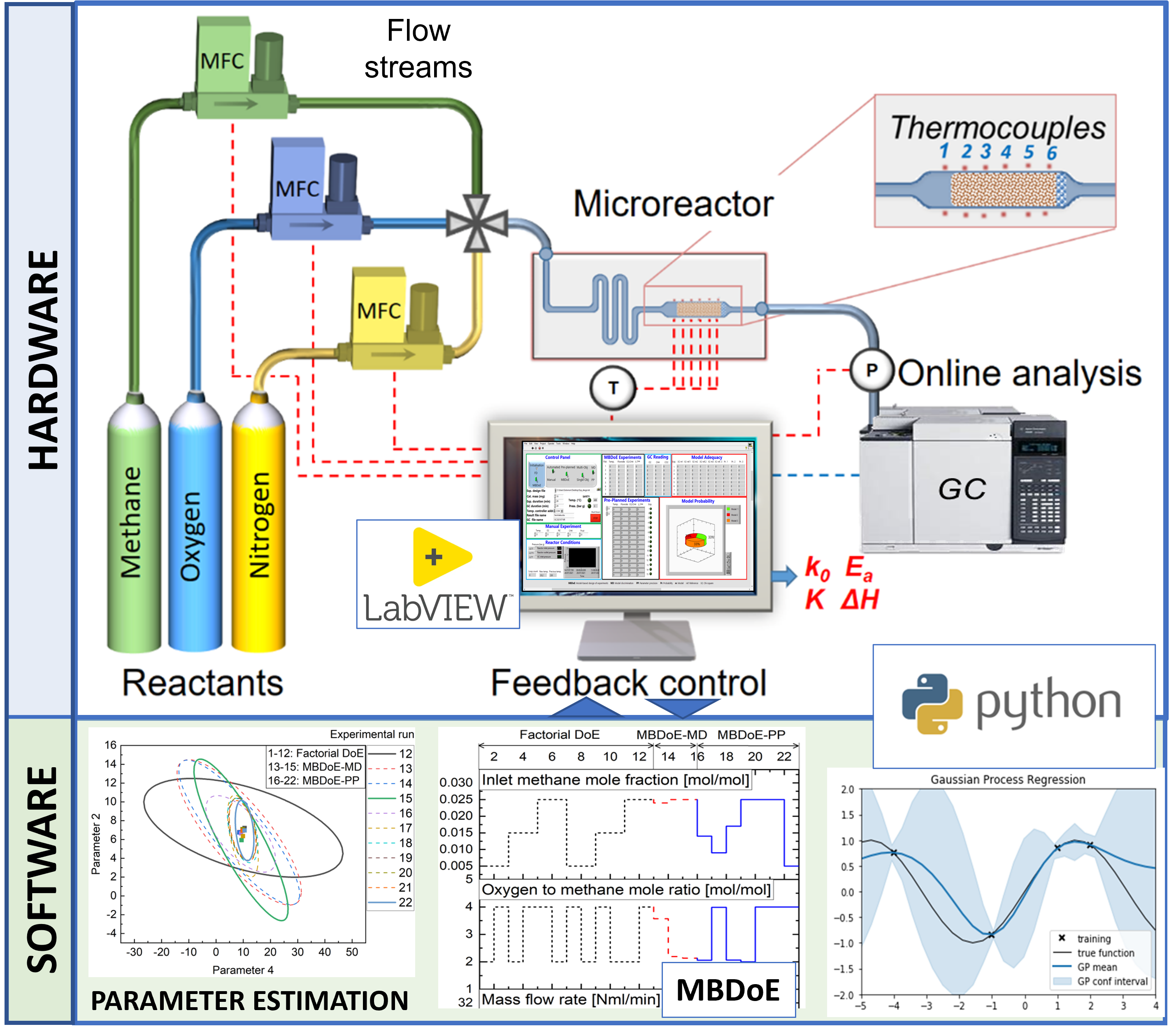

Smart laboratory platforms

Smart laboratory platforms have been developed to drastically reduce the cost of experimentation for model development by integrating automated microreactor systems (hardware components), cloud-based computing, advanced model identification and optimisation algorithms (software components) to identify appropriate reaction models online. In these platforms, model-based design of experiments (MBDoE) methods are employed to i) discriminate among potential kinetic models; ii) estimate the set of model parameters precisely by designing optimal experiments that generate the data needed for rapid validation of kinetic models without human intervention. The computational framework of the platform was developed in Python programming language and was integrated into a LabVIEW program of the microreactor system. A new Pyomo-based parameter estimation module was employed in the framework for the efficient solution of online parameter estimation problems.

Cognitive chemical manufacturing

In the EPSRC project Cognitive Chemical Manufacturing, Sargent Centre researchers have developed a software tool exploiting Gaussian Processes (GPs) as surrogate models to model reaction systems under uncertainty to design automated experiments run remotely at a partner institution using cloud-based services. The project combines automation, flow chemistry technology, machine learning (ML) and MBDoE to identify the best experimental conditions for model validation and move towards the development of an intelligent system for autonomous decision-making to facilitate the cost-effective continuous manufacturing of chemicals.